- Laser LT FIBER EVO ADIGE

– for adjusting the length, shape of the front and punching holes - Laser LT 5 ADIGE

– for adjusting the length, shape of the front and punching holes - BTM CNC bandsaws

– for cutting bundles of metal shapes, especially for cutting shapes with a rectangular cross-section - Automatic circular saw ADIGE

– for cutting sections of metal shapes with a round cross-section

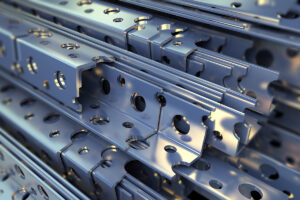

Lasered profiles

In addition to our own production of thin-walled profiles, we also offer their further processing. This includes cutting into lengths required by customers, punching holes and modifying the front of metal shapes.

Our machinery:

Production options of LT FIBER EVO:

- Cutting of standard closed profiles

- Round shapes from 12 to 120 mm in diameter

- Square with side length ranging from 12 to 120 mm

- Rectangular, oval and flat oval with a circumradius up to 170 mm - Cutting of standard open profiles

- L, U, C and I shapes – in sizes ranging from 30×20 to 120×120 mm

- 40x5 mm and 120x5 mm flat bars - Cutting of special closed and open profiles

- Cross-sections with a maximum circumradius of 170 mm - Profiles lengths

- The input length for metal shapes is 3,200 - 8,500 mm, and a maximum of 7,400 mm for strip steel

- Maximum input length: 6,500 mm - Wall thickness of profiles according to material

- Carbon steel - max. 6 mm

- Alloy steel (stainless) – max. 5 mm

- Aluminium alloys – max. 5 mm

- Brass – max. 5 mm

Use of lasered metal shapes:

- Reinforcement for plastic door frames

– punched holes for the lock, handle, metal fittings, etc. - Profiles for steel structures

– adjusted front of metal shape (cut at an angle, punched locks for counterpart), preparations for bending (with a rounded or sharp edge), punched holes, engraved position marks and names of parts. - Profiles for the construction of fencing

– punched holes for attaching clamps for tension wires or finished fence parts.