Profile centres

Up to 100,000 tons of steel profiles per year, precision in every piece.

We understand our work

Broad portfolio

Definition of quality

Stability

Flexibility

Reliability

Certification

Where we deliver

Quality material

Profiles and tubes are manufactured from hot-dip galvanized steel strips with a galvanization of 100 - 275 g/m² and cold-rolled or pickled sheet strips from first-class suppliers.

Profiles with a requirement for long-term corrosion resistance (e.g. for PV plants) are made from sheets with a special ZnAlMg surface treatment; these coatings protect natural resources, as less zinc is used in their production than in conventional production, but provide the product with up to four times the corrosion protection.

All materials are subject to initial inspection and their quality is certified by the manufacturer.

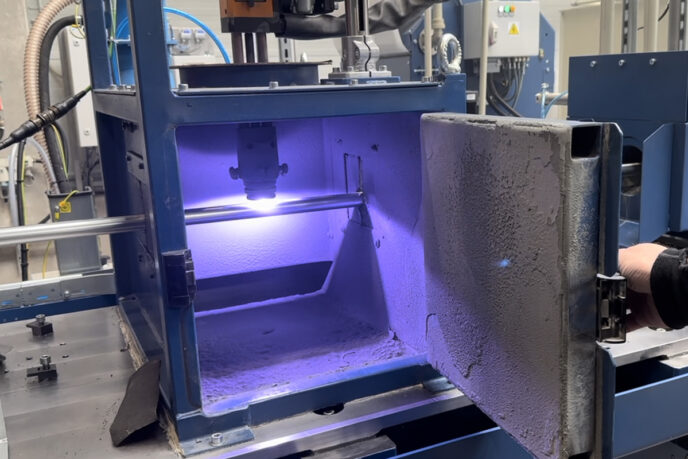

Technology maturity

Our modern machinery and experienced team allow us to produce a whole range of new shapes according to the technological process.

- 21 roll forming lines

- 3 high-capacity welding lines

- 2 ADIGE LT 5 and ADIGE LT Fiber EVO laser-cutting machines

- 2 MOD 715 NC saws

- 3 low speed saws

- 2 laser saws ADIGE TS 72

- 2 NC lathes for wheels manufacturing

- 2 cut-to-lenght lines

Profile centres

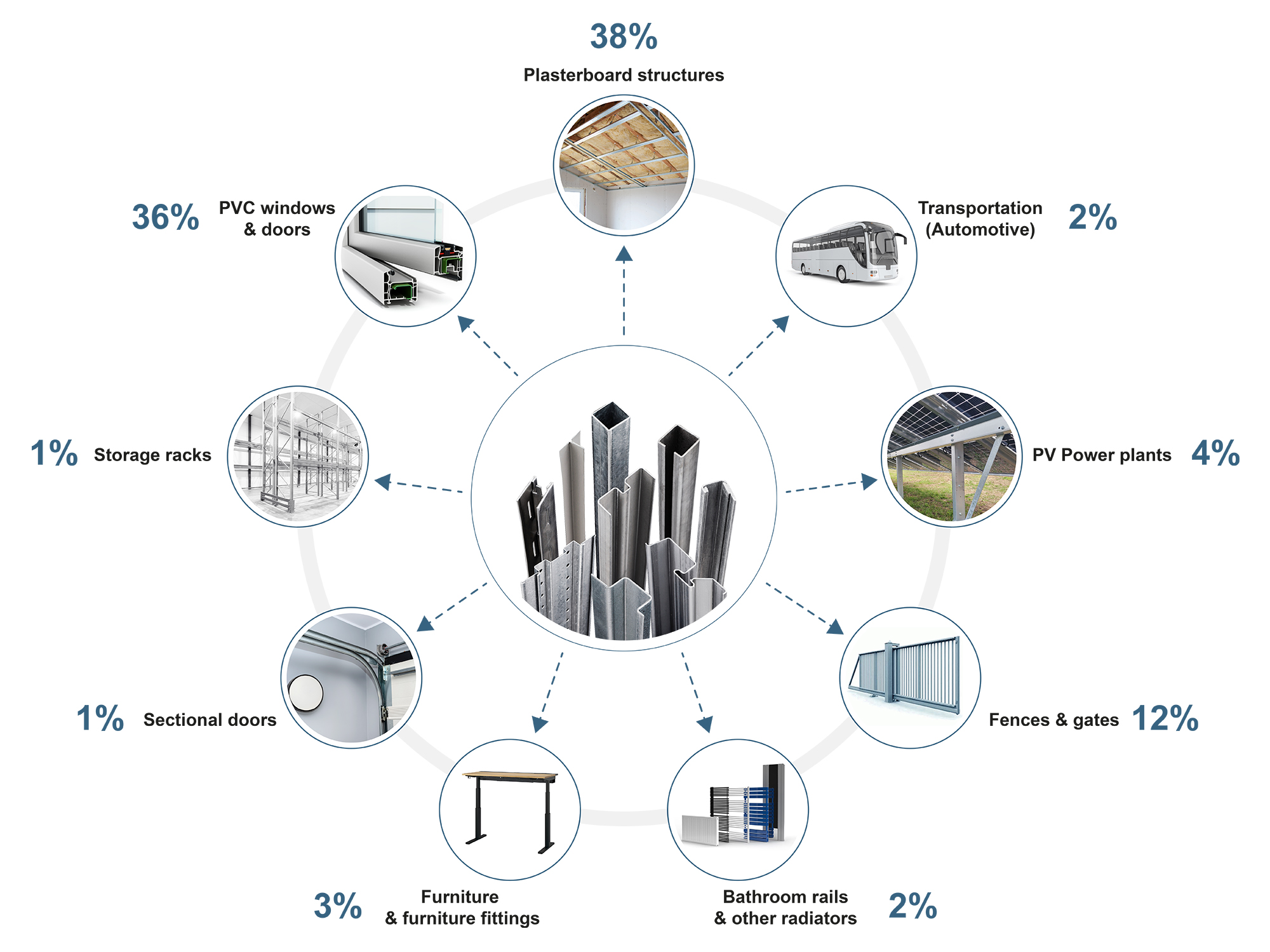

In our 3 profiling centres we produce open and welded profiles from galvanised, cold rolled or pickled strips with a thickness of 0.4 - 3.5 mm. The product range includes over 800 types of profiles for a wide range of industrial applications and also special profiles with increased corrosion resistance (C3, C5) suitable for installation in humid areas or for demanding industrial applications.

- The lengths of our metal shapes and packaging are chosen by customers. Our production capacity is 100,000 tonnes of profiles every year.

Profile centres in numbers

on the market since 2008

number of employees

production & storage area

production capacity

variety of our profiles

profiles produced in 2022

Export

We deliver our steel profiles to 15 European countries