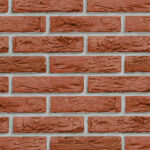

Wide range of patterns, exceptional properties

In addition to organic coatings, we can also apply laminating films on our coil coating line.

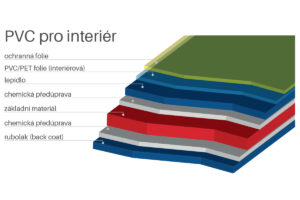

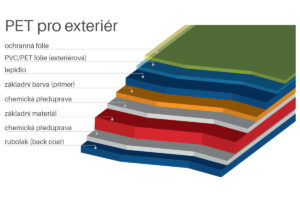

In some cases, the required surface properties of the sheet metal can be better achieved with laminating films that are applied on the coil. First, adhesive heated to 160-180°C is applied on the coil with a roller, and then the laminating film is rolled onto it.

For indoor and outdoor use

Laminated metal has great flexibility and strength, and it enables creating special patterns. Some films are primarily intended for outdoor use (weather resistance), while others are used indoors (resistance to stains, scratches, aggressive chemicals). These properties make laminated sheet metal suitable for use in the production of household appliances, sheet metal furniture, cold rooms, elevators and other demanding industrial applications.